Your school may be sitting on a goldmine of learning opportunities, in the form of old smartphones.

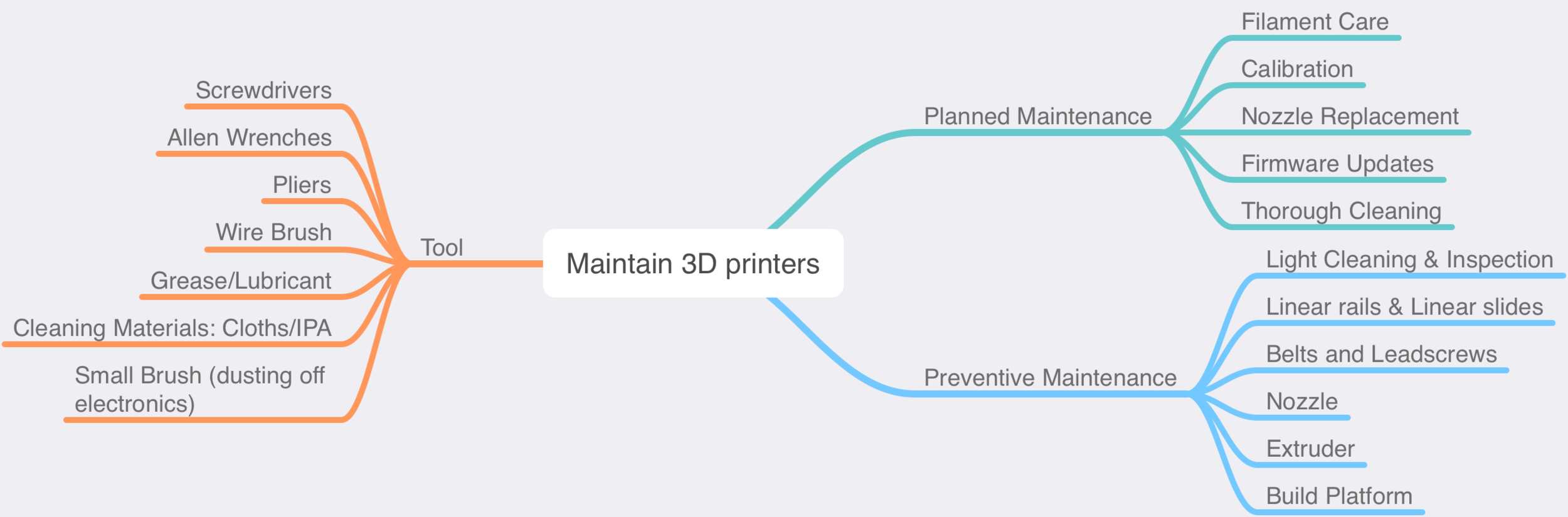

3D Printer Maintenance [Part 3] - Planned Maintenance

While regular preventive maintenance will help keep your printer running smoothly, there are some extra tasks you can carry out once or twice a year to further enhance your printer's performance.

Filament Care

Dust is the natural-born enemy of the 3d printer nozzle, as it only takes a small amount to cause a partial or total blockage and dust can also build up and cause unwanted friction in the bowden tubes. Check your clip-on dust filters as the foam should be cleaned or replaced if it has worn out. If you are not yet using clip-on dust filters, check out this print model by Haprog that is fast to print and a simple way to wipe the filament as it enters your extruder. While it is tempting to think this item can act as an oiler, please refrain as Stefan Hermann has tested oiling and found it overall a disadvantage.

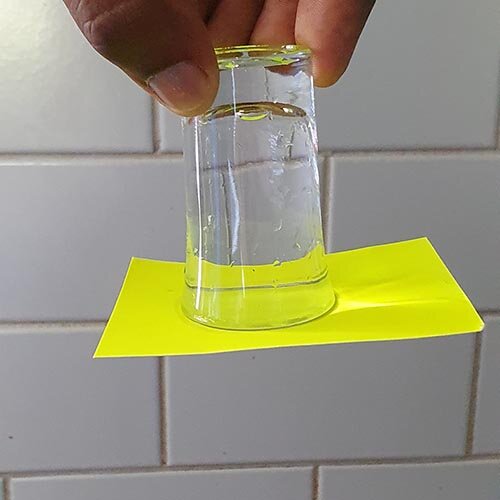

If your printer is in a damp environment and you notice the filament bubbles when printing (absorbed moisture boiling out when heated), build a dry box from a cheap airtight food storage container as a practical way to keep your filament dry. This dry box has the added benefit of protecting the filament from dust and will prolong the shelf life of the filament once removed from its vacuum-sealed packaging.

Calibration

A well-maintained printer should hold its calibration for a long time, but it is wise to print a 3D Benchy or calibration cube and confirm that the size and quality are expected. I recommend dating this calibration part and keeping it as a reference to check the quality is staying stable over time. If you print a 3D Benchy, check for print quality, accuracy, cleanliness, and the other characteristics described on their official website, as the model has lots of features to test the performance of your printer.

If your printer calibration has started to drift, then either follow your manufacturer instructions or the following guides can help with a general calibration process, including correctly setting the extruder’s steps per millimetre.

Nozzle Replacement

While it may be hard to believe, the constant rubbing of filament inside the nozzle tip will open up this precision hole and deform its shape, making it hard for the printer to hold the same tolerances as when new. Harden steel nozzles or ruby tipped nozzles that do not suffer erosion are aimed at printing extremely abrasive (carbon or metal filled) filaments and are not worth the extra cost for standard printing. A far more cost-effective option is to plan to change the nozzle 1-2 times a year with heavy use as when purchased in a muli-pack.

Please check your user manual for the correct nozzle changing method for your printer, but here is a link to swap out a nozzle on an E3D V6 style hot end (one of the most common). Be careful during this process as the heater block will be hot, and much like cleaning, care must be taken to avoid damaging or touching the heater cartridge and thermistor wires.

Firmware Updates

Many modern 3d printers are open-source and have HUGE communities of users updating, upgrading and modernising the slicer and firmware that drives your 3d printer. It is a good habit to know what version of firmware your printer runs, as keeping it current will keep your printer at the cutting edge of functionality and address any safety issues the community has identified. Care must be taken when updating the firmware, as it is possible to wipe important information. Hence, it is always best to follow the manufacturers' recommendation for the firmware install method and version. This process is very quick and can often unlock new functions as the community moves forward together.

Thorough Cleaning

While keeping the printer clean and dust-free is a good rule of thumb, once or twice a year, you should aim to dive deeper and remove the dust and the unavoidable build-up of small bits of filament in the harder to reach areas. Check that the electrical control board is dust free as a thin coating can hide heat dissipation and encourage corrosion of contacts and the PCB. As print and hot end fans are critical for print performance, take the time to fully disassemble them, as they can build up internal dust or layers of very fine filament that is sucked in during everyday printing. A little effort to keep them clean will prolong their lives and avoid a fan failing or unexpectedly stopping mid-print. A set of new and clean paintbrushes are an excellent tool for this job, but having a vacuum at hand will help remove the dust rather than just pushing it around.

Now that you have finished these tasks, your printer should be in top-notch shape and have the best chance of becoming the easy to use and reliable machine. If, by any chance, something goes south during your test prints, this is the time to troubleshoot. However, this is unlikely to happen as you have now completed the OMGtech! 3D printer guide and, as such, should have a fantastic tuned and reliable 3D printer freshly serviced and reliable printer that you can trust to help your students engage technology to explore their creativity.

3D Printer Maintenance [Part 2] - Preventive Maintenance

Preventive maintenance is simpler and cheaper than after the fact repairs, so it is recommended to be performed regularly to keep your printer running smoothly and reduce the chance of unexpected failures. A small amount of routine work will extend the lifespan of components, reduce the costs associated with the eventual replacement of parts that wear out and avoid downtime needed for more extensive repairs.

👉 [PART 3] - PLANNED MAINTENANCE

How often you need to perform this maintenance is dependent on how much use the printer gets and the environment in which it is kept. A printer with light use or kept in a very clean enclosure (with air filter) will require a lot less frequent attention than a printer run-flat tack in a dusty room. Keeping a close eye on when a printer's performance starts to suffer is often a good indicator it is time to get out the tool kit and take care of whatever issue may be causing the loss in printer performance.

Light Cleaning and Inspection

The best way to get started is to unplug the printer from power and place it in an open space so that it is easy to inspect each area for signs of wear, broken or missing parts, build-up of filament blobs or dust/grime. Note down any damage or tasks that will need attention as you find them, as it can be easy to forget something small if you have to deal with a few different tasks simultaneously.

Start by giving the printer a light clean while doing an initial inspection as this is a chance to pick up any issues, and it is much nicer doing any following maintenance on a clean machine. A soft brush and vacuum cleaner make fast work of any surface dust and are perfect for quickly cleaning dust and stray strands of filament from fans and the hot-end heatsink. A damp rag can also be helpful for stubborn gunk on non-electrical surfaces. Cleaning dust and grime are essential as they can build up on the printer by clogging bearings, impairing bed adhesion or blocking fans, so it is recommended to clean your printer regularly or consider keeping it in a dust-free environment.

Once the machine is clean, inspect all cables, plugs and connectors are well seated in their sockets, show no signs of damage, and no wires are coming loose. Double-check cables that carry the high current to the hot end heater cartridge and heated bed show no signs of burning, melting, or discolouration, as this is an indicator of a bad connection that may cause sparks/fires.

Linear rails and linear slides

The bearing blocks or slides on your printer must be kept clean to avoid dust getting stuck in the ball races and lubricated to allow a smooth, resistance-free motion. Start by removing any dust from the rails by wiping it off with a clean rag. Then inspect the rail for damage, bends or corrosion as these can cause significant resistance. Once clean, it is essential to relubricate the rail quickly using the recommended product (light sewing machine oil can be used if your printer did not come with its oil or a recommendation) as this will protect the rail from rust. A light film is all that is needed and can be topped up as required. Putting this task off can lead to excessive noise and resistance on the stepper motors or misalignment of layers if the friction becomes enough to cause the stepper motor to miss steps during rapid accelerations.

Belts and leadscrews

Belts and leadscrew translate the rotation from the stepper motors into linear motion of the heated bed and hot end, so any damage, resistance or play will cause poor printing performance. Check the belts are appropriately tensioned by holding the belt pulley stationary (needle nose pliers are recommended) and then lightly moving the bed or hot end with your other hand. If you can see/feel the movement of the hot end or bed, then add a little more tension to the belt before rechecking. Leadscrews can be tested similarly by holding the coupling between the stepper motor and leadscrew or the leadscrew itself and then applying a small amount of movement to that axis. Most leadscrew nuts will have a tiny whisper of play, but if you notice this amount has grown over time or is very easy to spot, it is a sign to replace the leadscrew nut for that axis.

As there are so many different types of 3d printers, it is best to check your instruction manual as to the proper tensioning method, but in case you have misplaced your manual, check out the Prusa Printers tensioning guide for an overview of the process that applies to a wide range of similar open-source printers.

Loose belt tension can lead to belt skipping, print layer shift or a loss of printer accuracy as the printer wobbles around sharp changes in direction and degrading performance the faster you print. Printers with a direct drive extruder will likely suffer more from bouncing and ringing artefacts because of the heavy mass of the extruder motor, so extra attention should be paid when checking a bowden style printer as the print defects may not be as pronounced. Too much tension will cause extra resistance and strain on the stepper motor bearings or cause overheating, so aim only to put as much tension as required to stop a light pressure when holding the pulley stationary. If you find your printer has difficulty adjusting belt tension, consider finding a suitable replacement as most open-source printers will have a wide range of aftermarket (self printable) parts available for you to choose from.

Nozzle

The nozzle of a printer is where the plastic meets the print bed, so while small in size, keeping it happy has a significant impact on print performance.

Kick things off by preheating your hot end without filament loaded (to avoid dripping) to the upper end of the temperature range of the filaments you have run in the past and allow the entire hot end to heat soak at temperature for a few minutes. Be extremely careful to avoid the heater cartridge and thermistor wiring (which is very fragile and carries 24v DC power); use a cotton rag, small brass wire brush* or ceramic tweezers to lightly brush away any external melted plastic from your hot end heater block and nozzle. The hot molten plastic should lightly stick to the brush or cloth and is easy to make the heater block area look new again.

A small brass wire brush is the most effective tool for the job but being conductive poses a risk of shorting out the heater cartridge or breaking the very fine thermistor wires if care is not taken. The safest method is to turn the heater off via the LCD menu before brushing to avoid power on the heater cartridge wires when using a wire brush. Turning the printer entirely off is another option, but as soon as you finish, turn the printer on again as most require the hot-end heatsink fan to run any time the nozzle is above 50c. You may need to reheat the heater block if it cools too much while cleaning, but this should be quite fast and is still much quicker than replacing a heater cartridge or a printer's mainboard!

If this is a common problem for you, consider getting a silicone sock for your hot end as they are cheap and give a slight thermal stability bonus and make cleaning far simpler as you can remove the sock while cold and then flick off any stray filament.

Now that the outside is clean, I recommend using, as demonstrated by the Youtube 3d printing godfather, Thomas Sanladerer, the cold pull method as an efficient internal cleaning method that is less likely to ream out or damage the very fine hole at the tip of the nozzle. A fine pin and some careful poking can also work, but it is very easy to damage the nozzle unless you are incredibly careful.

If you don't keep the inside of the nozzle and melt zone clean, your printer is likely to suffer under extrusion, partial or complete blockages and reduce retract performance, which increases the chances of blobs on your print surface. Keeping the outside of the hot end clean will help you avoid bits of old filament dripping onto your current print, but also small flyaways have a nasty habit of catching the first few layers and pulling them up, causing a print to fail, so keeping it clean is well worth the effort.

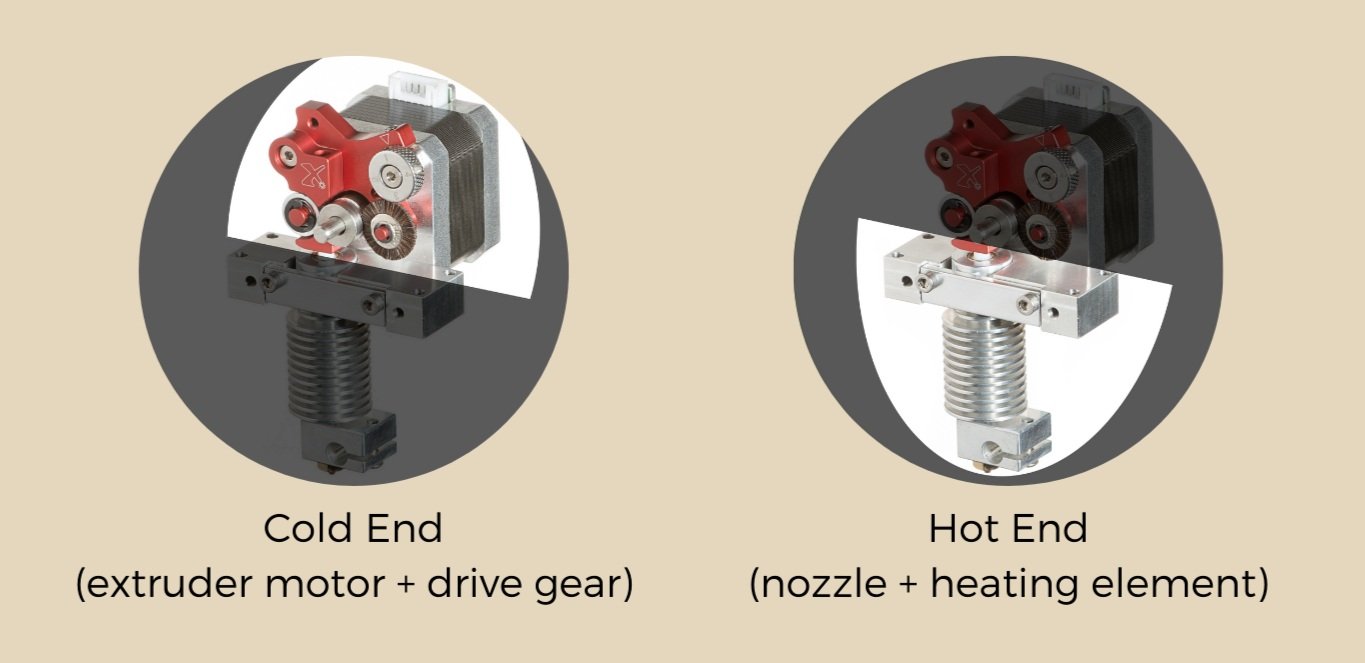

Extruder

Extruders use a drive gear to grip the filament and push it down into the hot end. Regular use can build up an accumulation of ground filament particles that can clog the drive gear teeth and reduce the grip causing under extrusion or filament slip. Refer to your user manual about how to get into the drive gear area. A small clean paintbrush and vacuum cleaner can often make short work of any build-up. A toothpick is a helpful tool to scrape any clogged drive gear teeth clean without risking damage to the surface of the gear.

While this list may seem a little daunting at first glance, a little bit of practice becomes very manageable and rewarding as you will gain a deeper understanding of how your printer works. More importantly, you will gain the confidence to know your printer is in peak performance and can be a trusted tool to help students explore their creativity and become confident with the joys of rapid prototyping within the classroom.

Build Platform

The first layer of a print is arguably the most important; it sets the base for every layer that will come after it. A perfect first layer will give the best print results as you avoid elephant footing and with good adhesion, the prints will stay locked onto the build platform during the entire printing process, so it is worth spending some time to get the printer bed dialled in.

Start by deep cleaning the print surface to remove any contamination or product build-up as it only takes a tiny amount of contamination, dust or oil from fingerprints to cause bed adhesion to suffer. Removable print surfaces (spring steel, G10, glass etc.) make this task easy as it is possible to soak the removed surface in hot soapy water to soften any glue stick or products, then rinse clean with fresh water and allow to drip dry. If your bed is not removable, then using a paper towel or rag laid on the printer bed then dripping a small amount of water to dampen it will give you a similar effect soaking effect with less chance of dripping but for safety, always unplug your printer as a spill could end in disaster.

Once clean, it is worth checking your bed surface is in tram with the motion system by moving the print head close to the print surface and using a piece of paper as a feeler gauge to note the relative Z height in the middle of the printer surface and then each corner. With these measurements, it is easy to see if you should use the bed levelling adjustment screws to tram the print bed to the movement of the printer as it is best practice to set the bed as physically flat and trammed before allowing the software-based mesh bed levelling, that most modern printers come with, to make the last smaller software base adjustment.

Once your bed is clean and trammed, then it is ready to set your first layer height using either test prints or, if available, the built-in calibration function that allows you to adjust the Z height on the fly while printing a long single line that zigzags its way across the print bed.

As it is likely you may have touched your bed during calibration or removing the last print; it is a good habit to wipe the bed down with the recommended cleaner (solvents can break down some print surfaces, so always check with your user manual) before each print using a clean lint-free cloth.

3D Printer Maintenance [Part 1] - Tools

3D printers are fantastic classroom devices when running as expected, but as any long-term 3D printer users know, they can suffer from poor performance when not properly maintained. We will use three blogs to introduce you to the maintenance process of 3D printers, including Tools, Preventive Maintenance and Planned(Seasonal/Annual) Maintenance. Here is the content outline that we will cover over the next few weeks to help you get the most from your investment.

👉 [PART 3] - PLANNED MAINTENANCE

3D printers allow students to transform an idea into real-world objects using the power of CAD; however, a poorly performing printer can ruin any aspiring makers' day. Just like any workshop tool, 3D printers need regular maintenance to assure they work as expected, provide high-quality printing results and can be relied on to finish prints without the need for multiple attempts.

Regular maintenance is critical to achieving the best results, and while sending it out for servicing is one option, we highly recommend rolling up your sleeves and learning how to do it yourself! Most tasks are fast to do, allowing you to stay on top of issues as they arise rather than waiting for an annual service, and the money saved can be spent on printer upgrades or extra filament.

We recommend referring to your printer's user manuals for specific instructions; however, below is a general guide for those wanting to keep their 3D printer running like a champion.

Build your own 3D Printer Tools Kit:

Before starting any work, it is best to ensure you have the tools and supplies needed at hand and ready to go. Below are the common tools for assembly, repair and maintenance of most 3D printers:

Allen wrenches

Small spanners

Screwdrivers

pliers

A brass wire brush

Grease or lubricant for axes and guides

Cleaning materials (cloths, general surface cleaner and IPA)

A small brush for dusting off electronics

Vacuum Cleaner

If your printer has its own toolset, check that it is all present and good condition. It is encouraged to keep a printer only toolbox near the machine as this will help fix a small problem fast and efficient by having the tools at hand and ready to go when needed.

Whaea Zoe's Top 10 Holiday Reading List (In no particular order)…

By Zoe Timbrell - Kaiwhakahaere at OMGTech!

Anyone who knows me, knows I plan on spending the entire holiday curled up with a pile of great pukapuka. Fair to say I bought a small library during the lockdown and can't wait to read them all. Here are a few of my favourites I think everyone should add to their summer reading list too.

Polynesian Panthers Pacific Protest And Affirmative Action In Aotearoa New Zealand 1971-1981

Melani Anae, Leilani Tamu, Lautofa Iuli

This year I had the privilege of attending the Dawn Raids Apology; an event acknowledging and formally apologizing for the racism and discrimination our Pacific Peoples faced in the 1970s and 1980s in Aotearoa NZ. These actions formed the basis of the systemic discrimination in our education system that still exists today. This is a critical part of our history that every educator should know about and this book is a great place to start.

Imagining Decolonisation

Rebecca Kiddle, Bianca Elkington, Moana Jackson et al.

Practising Decolonisation is critical for the future of our education sector; but for many, understanding what it means and where to start on your own decolonisation journey can be overwhelming. This little gem is an incredible book to start you on your path. Written in short articles by many amazing authors I highly recommend this for everyone.

Also as a side note, BWB Texts are incredible and accessible texts and there are so many great ones I'd say buy a bundle!

Homo Deus - A Brief History of Tomorrow

So this book came out a few years ago. I LOVED Homo Sapiens, his previous book (I personally think this should be a social studies text in every class) so I grabbed this as soon as I could. This book explores the near future and what things are shaping the future of humanity. Yuri has a super accessible writing style. This book will get your brain sparking about what future it is that we want, and how science, technology, philosophy, economics and more can be used to create it.

Coloring in the White Spaces: Reclaiming Cultural Identity in Whitestream Schools

Dr Anne Milnes work is transformative. She is one of my education heroes and every single teacher in Aotearoa NZ should read this book. Then take her courses. I cannot recommend them highly enough. This book examines the struggle against racial and cultural inequity in educational systems and how one school and its community have changed that, and how you can too.

Art Matters

Neil Gaiman

I picked up this book in a small bookshop on the Island of Santorini. I had spent the trip teaching myself to draw and this book spoke to me (well, showed me anyway as it’s mostly pictures). I was inspired by the idea that all of us are artists but at some point, the ART is taken from us (Ken Robinson has a lot to say on this). We feel we aren't good at it. But ART MATTERS! And being creative is important for the soul. This creative call to arms will reconnect you with the Artist that lives inside.

The Pōrangi Boy

Winner of the Young Adult Fiction Award, New Zealand Book Awards for Children and Young Adult, in 2021. This book was written by Shilo Kino for “kids like me who struggle to see themselves in stories.” Her debut novel is incredible. Telling stories that haven't been told but need to be; creating fiction for rangatahi Māori that they can identify with. Hopefully, we see this as a text in schools across the country in 2022. So give it a read and get a classroom set for your local school.

Her Say - Survivors of Domestic Abuse Tell Their Own Stories

TW - Intimate partner violence

This book is the most incredible book I bought this year, and you should get it too. It is powerful, moving, raw and real. Told in their own words, these are the stories of New Zealand women who have lived in - and escaped - abusive relationships. It is full of hope and empowerment as these wāhine toa rewrite the narrative and their own outcomes. Bonus - all royalties from sales go to The Aunties to support their work.

Ngā Kete Mātauranga

Jacinta Ruru & Linda Waimarie Nikora (eds)

This book is deeply personal, and each of the 24 authors offers us a massive gift in sharing their own stories. Through their perspectives, we can understand how Te Ao Māori can be interwoven into research. Understanding and valuing Mātauranga and Tuku Iho is critical to our commitment as Tangata Tiriti. For anyone undertaking research in or about Aotearoa, this is a must-read.

Kei te Kīhini o te Pō

I am LOVING the release of all my childhood favourite books into Māori. Particularly the Maurice Sendak ones, which I can spend hours looking at. Kei Reira Ngā Weriweri has also been released and is on my Christmas present list. These are a great way to support your Reo journey with familiar stories that you can read aloud and already know the exciting parts and when the monster voices come in. Or, in this case, ease your littlies into whakamoe and moehewa.

First Readers in Māori

Ok, so this is more like ten books, but hear me out! This little collection is right about where my current Te Reo Māori reading level is, and they are designed for this. I read them to my nieces and nephews, and it's fantastic, I get to practice, and they get rawe stories told in Te Reo Māori. I also started on my Samoan language journey, and I got these in Samoan. This is great as they are the same stories, so it's helping my understanding. If I had to pick one, I'd say start with Kia Ora Hana Kōkō, and your Kirihimete list will write itself.

Copying Any Google File!

While we are tech agnostic here at Pam Fergusson Charitable Trust, we’ve chosen to share our lesson plans using Google Folders.

The majority of the teachers we work with use Google, or at least everyone can access it (the links we share are usually “anyone can view”) so it’s an easy-peasy solution to get our content in your hot little hands.

One of the most common questions, (or rather internal Google requests) we get is “Can I have edit rights”?

It’s a fair question, you want to make the content your own, but what most of you want to do, is make a copy really!

So here’s a top tip for you all!

Simply by changing the word “edit” in the link to the word “copy” you make a copy straight in your Drive!

BYOD Overload with Keith Paterson

Happy Holidays!

The holiday season is almost upon us! We thought we would do a #STEAM flavoured version of the Advent calendar for all of y’all to celebrate… whether you love all things Christmas, or you don’t celebrate it at all, here are TWELVE awesome holiday-themed STEAM activities for your tamariki to sink their teeth into!

Most of these are from our Kaiako Wharenui, which is our jam-packed digital repository full of lesson plans for all our rawe kaiako (awesome teachers) Aotearoa-wide.

If you are a parent, don’t despair, you’ll be able to do all these activities too! All the programs mentioned below are free, or they are offline resources.

Day 1: Blast off!

Construct a rocket!

Day 2: Minecraft Education

Take an hour and learn some coding with Minecraft: Education Edition

Day 3: Values-based Games

Make some games rooted in the values of you, your whānau and your community

Day 4: LED Greeting Cards

Make a greeting card that lights up!

Day 5: Gravity Free Water

Defy gravity with SCIENCE

Day 6: Sort me!

What is a parallel sorting network? How do computers sort data?

Day 7: Santa’s Binary Challenge

Psst Santa has a secret!

Day 8: Find the Toys!

Make a Christmas Find the Toys Animation in Scratch

Day 9: Animate a character

Animate yourself or a Kirihimete image using Piskel

Day 10: Hour of Code

Learn how to code in just one hour!

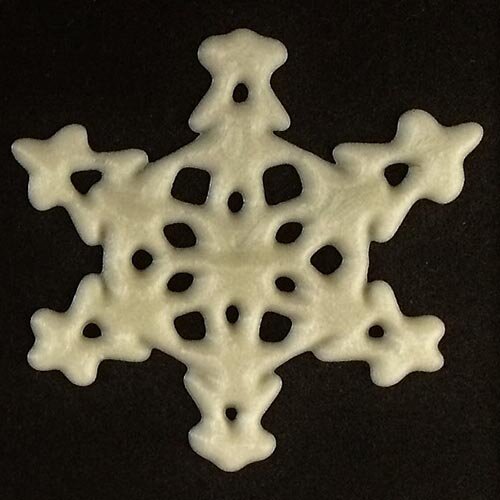

Day 11: Design a snowflake

Let’s learn all about snowflakes!

Day 12: Make a comic strip

Illustrate your favourite Christmas Carol

Tapena sou ōso mo lau malaga - Samoa Language Week

Talofa Lava!

Samoa Language Week is from Sunday 24th May to Saturday 30th of May this year and the theme is Tapena sou ōso mo lau malaga or in English - Prepare yourself a gift for your travels.

This year's theme urges us to prepare for the journey ahead. It highlights the need to honour, respect and share the gifts of our life's journey.

Because of COVID-19, we couldn’t celebrate Samoa Language week with a big public event, so we thought we’d share a cool digital technologies activity that shares the gift of language through the use of digital technologies.

In our example, we introduced Samoa Language week. We suggest you record some tautalaga (phrases) in gagana Samoa (the Samoan language). Here is a good source of tautalaga on Manuatele.net. Click here to check them out.

Give it a go! Click on the green flag and let Sosefina tell you all about Samoa Language Week

Do you want to make your own?

If you are a faiaoga (teacher) in a NZ School, you can check out a slightly more complicated version of this Scratch program using Makey-Makey here. That link takes you to our digital wharenui where we share lesson plans with all our amazing teachers nationwide. It’s free to join and there is loads in there.

If you are a matua (parent) and you just want to give it a go with your fanau (children), keep reading!

Step 1: Go to https://scratch.mit.edu/, click on Create right at the top. If you want to save your work to check out for later or to share it with aiga (family) and uo (friends), then click on Join Scratch on the top right. You will have to help your child through this process, if they are under 13, you will need to confirm their account for them. MIT’s Scratch is completely safe and a great way for your kids to get into coding!

Step 2: Create or draw a suitable background. We downloaded our amazing sunset from Wikicommons, but there are many amazing places you can download images that are free to use, or even better, get your child to draw their own.

To upload a background, put your mouse over the “New Background” icon on the bottom right of the screen, and click on Upload. Find the image you have prepared and click on Open.

Watch this handy-dandy gif to see how.

Step 3: Choose a suitable character. Our fafine (girl), Sosefina, is originally called Dani in the Sprites section. We first got rid of the cat (we love the cat, but I wanted someone that fit in a bit better on our beach. Click on the wee cross rubbish bin next to where it says Sprite 1 on the bottom right-ish of the screen. Then click on the Cat with a plus sign to find Dani. Also, as you will soon see, when you add Dani in, she’s a bit too big! You have to change the Size on the bottom right of the screen. Then, lastly, you should rename Dani (if you want to, you don’t have to), we chose the beautiful Samoan name Sosefina.

You don’t have to pick Dani, you can pick anyone else from the Sprite library, or your child could draw their own. Instead of clicking on the Choose Sprites button, they have to click on “Paint”, or Upload (if you have scanned in their artistic creation)

Check out this handy dandy gif to see how:

Step 4: Record your message. We need to decide what it is we want to say. Work with your child to figure it out together, perhaps choose a tautalaga from Manuatele.net. Type it into something so your child can read it clearly. You will also need it in Step 5! Click on your character, click on Code on the top left. Then in the Events Bubble on the left, you will find a command called When this sprite clicked. Drag that into your coding window. Then look in the Sound bubble. Find the one that says Play sound pop until done. Drag that into your coding window and click it to your yellow event block. Click on the down arrow next to pop and click on record. Get your child to record the message. You will have to have a microphone for this bit. When you have finished recording, click on Stop recording. Depending on how long the recording is, you might need to drag the arrows out to make sure you include the whole thing. Then click on Save. Delete the default “pop” by clicking on its rubbish bin with the cross, then make sure you select “Recording1” in the dropdown.

Check out this handy dandy gif on how to do it:

Step 5: Add the speech bubble. Click on your character, click on Code on the top left. Then in the Events Bubble on the left, you will find a command called When this sprite clicked. Drag that into your coding window. Then look in the Looks bubble. Find the one that says “Say Hello! for 2 seconds”, drag that into the coding window, and click it to the Yellow Event block. Then type your message you decided to say into the bit where it says Hello! (delete Hello first). Change the 2 seconds into the number of seconds you noted down in step 4 (ours was 20 seconds).

Check out this handy-dandy gif to see how:

And now you’re all done! Test it by clicking on your character and you should see the speech bubble and hear your narrative!

Ia soifua ma ia manuia - Be Well and Prosper!

Kia kaha mana wāhine!

It’s International Women’s Day! (well it is if you are reading this on the 8th of March 2020!)

We have been celebrating International Women’s Day for well over a century. The first gathering was in 1911 and we’re still here…

The theme for this year is #EachForEqual - Individually we’re all responsible for our own thoughts and actions and together we can actively choose to challenge stereotypes, fight bias, broaden perceptions, improve situations and celebrate women’s achievements worldwide.

Here is a message from our kaiwhakahaere, Zoe Timbrell, for all you kōtiro and wāhine out there!

And we’ve also gathered some of the mana wāhine in our extended whānau to take a few minutes out of their day to give you a message for #IWD2020

Lets work for an equal tomorrow, today.

Emily is an electrical engineer who has a (self-confessed) obsession with self-driving cars, electric vehicles, horses and rockets. She has been one of our amazing volunteers for years and is smashing through all the stereotypes in her various roles in major tech startups here in Aotearoa! Check our her personal site here.

Ete is one of our amazing graduate developers and an all round bundle of energy that the rest of us can’t keep up with. She is also our community manager on the Voluntarily project and uses her technical skills and her amazing people skills to translate between the geek speak and the humans! Connect with her here on LinkedIn.

Matilde is our Events and Programme Manager and brings a bit of European flair to everything that she does. You’ll find her being on the forefront of running our technical programmes making sure that we don’t forget or overlook any of the most vulnerable in our whānau. Connect with her here on LinkedIn.

Sez is a developer and one of our amazing long-time volunteers! She was instrumental at bringing her engineering and developer’s eye to all our events processes and bought a level of calm to the chaos that has held us in good stead throughout the years! Connect with her on LinkedIn on here.

Tash is a cybersecurity analyst and another of our long-time volunteers! Tash is always constantly learning and is a strong advocate for getting more Māori and Pasifika into STEAM and more wāhine (women) into cybersecurity. Connect with her on LinkedIn here.